Managing Engine Temperature in Winter

Living in Southern New Jersey, I’m fortunate that winters here aren’t as harsh as in New England. However, temperatures still hover in the mid-30s to low 40s during the colder months, which can affect how your airplane operates.

Recently, I noticed my engine temperature maxing out around 150˚F during flights—much lower than the temperatures I’d typically see in summer. That got me wondering: do I need to take action? After seeing posts about pilots covering their cowlings, I started asking questions. The unanimous answer was a resounding yes.

Why Engine Temperature Matters

It’s crucial for your engine to reach and maintain its normal operating temperature for at least 10 minutes during a flight. This ensures that any water in the oil evaporates, preventing it from lingering in the oil tank and engine. If left unchecked, that moisture can lead to corrosion inside the engine, potentially causing costly damage over time.

Some signs of corrosion to watch for include rust on the dipstick (especially on the underside where moisture collects) and rust inside the oil filler tube.

Finding a Solution

If you notice your engine running cooler than it should, consult your mechanic for advice tailored to your airplane. Every plane is different, and what worked for me may not work for you. That said, here’s how I addressed the issue in my Cessna 140—with guidance from my mechanic.

The goal is to limit the amount of cold air entering the cowling and cooling the engine too much. Some pilots fabricate custom cover plates for their air inlets, while others use tape for a quicker fix. I opted for tape since I needed a solution right away, realizing it had been far too long since my engine had run at full temperature.

My Approach

On my Cessna 140, I used good-quality duct tape to cover the air inlets on the cowling, as shown in the photos. You’ll notice the tape on the right is horizontal—this was intentional to avoid blocking the heater air intake (I think) in the bottom left corner.

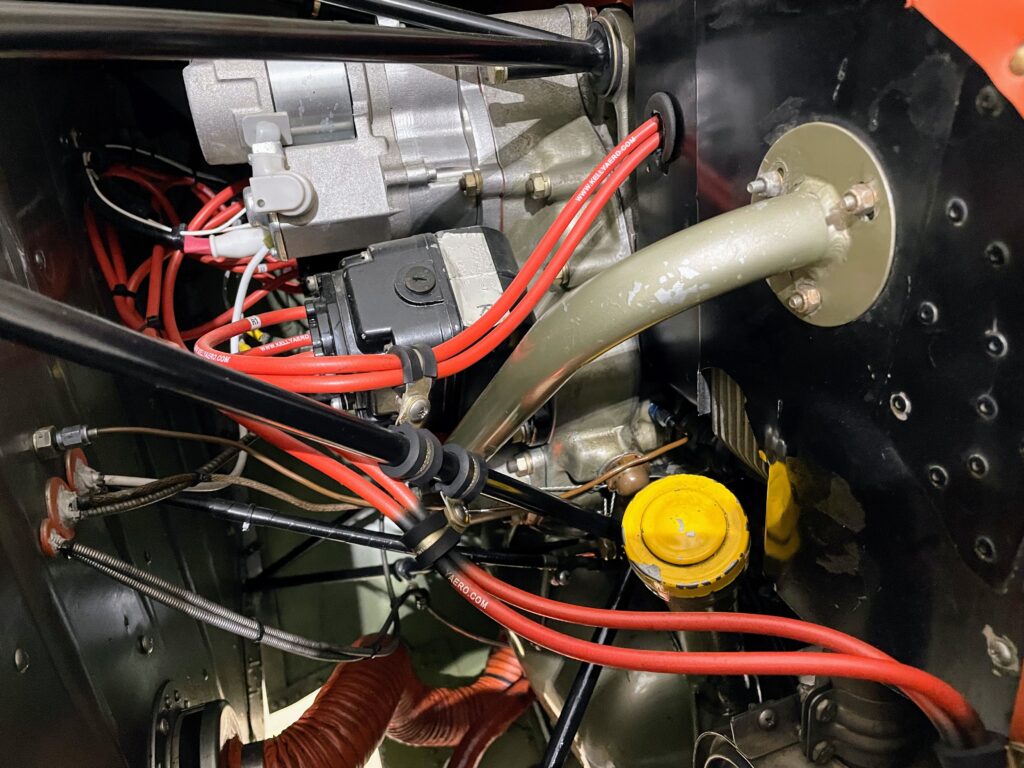

Additionally, inside the cowling, there’s an opening with a pipe that directs cold air from the front through the baffle and down toward the oil pan. I covered this opening with metal tape to withstand the higher temperatures in that area.

After making these changes, I saw engine temperatures during my next flight range from 185˚F to 190˚F—right where I wanted them! This was on a day when the outside temperature was about 38˚F.

Monitoring and Adjustments

I plan to keep an eye on the engine temperatures to ensure they don’t climb too high on warmer days. Depending on how the weather shifts, I might need to adjust the setup, but I’m hopeful this solution will hold until spring. Next year I’m going to try to find or fabricate a nicer solution for this problem.

If you’re experiencing similar issues, don’t wait too long to address them. A little preventative action can go a long way in protecting your engine during the winter months.

Update / Adjusting for Warmer Days

A day in the mid-40s came along, so I took the airplane up with the same setup I had previously used. This time, my engine temperatures climbed to 200˚F—right at the bottom of the red zone on my gauge. That was a bit warmer than I wanted, so I made an adjustment.

Instead of fully covering the inlet hole through the baffle inside the cowling, I reduced the coverage to about half. On my next flight, this brought engine temperatures down to around 165˚F (if I remember correctly), which felt like a much better balance.

Now that temperatures are starting to warm up here in Southern New Jersey, I’m hoping to remove the tape from the front of my plane soon. Looking ahead to next winter, my plan is to fully cover the baffle inlet only when temperatures are in the mid-to-upper 30s or lower. For anything in the 40s, I’ll keep some airflow open to maintain better temperature control.

Managing engine temps in winter is definitely a bit of trial and error, but it’s worth the effort to keep things running smoothly and prevent long-term damage.